StarGate M2L DHL Exel Slovakia, s.r.o.

Location: Bratislava

Function: internal logistics supporting production of motor vehicles

Capacity: logistics for 400 000 vehicles annually

Employment: 1200

M2M products implemented: M2L

Background

Ever-growing motor vehicle production in the Bratislava facility demanding high levels of labor flexibility combined with increasing demands in work quality generates new challenges for DHL every day.

There was a need to simplify the picking of parts according to a production plan for a particular car at the department's desk.

Requirements

- The system guides an operator to a correct location in the warehouse.

- It also allows for one person to simultaneously pick parts for multiple vehicles.

- Automated process of the parts ordering.

- Checking the correctness of parts unloading.

- Preservation of original racks and large boxes.

Our tailored solution:

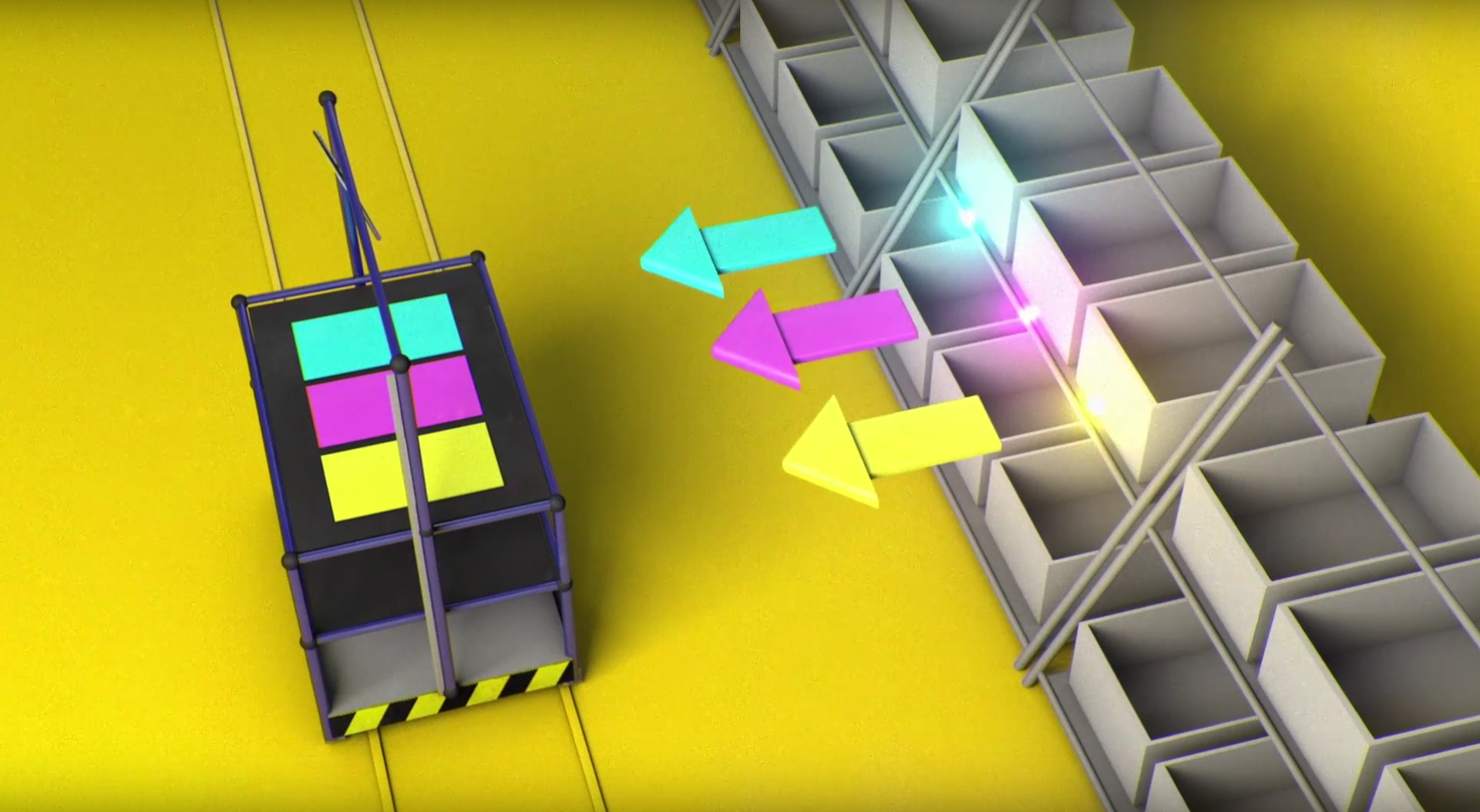

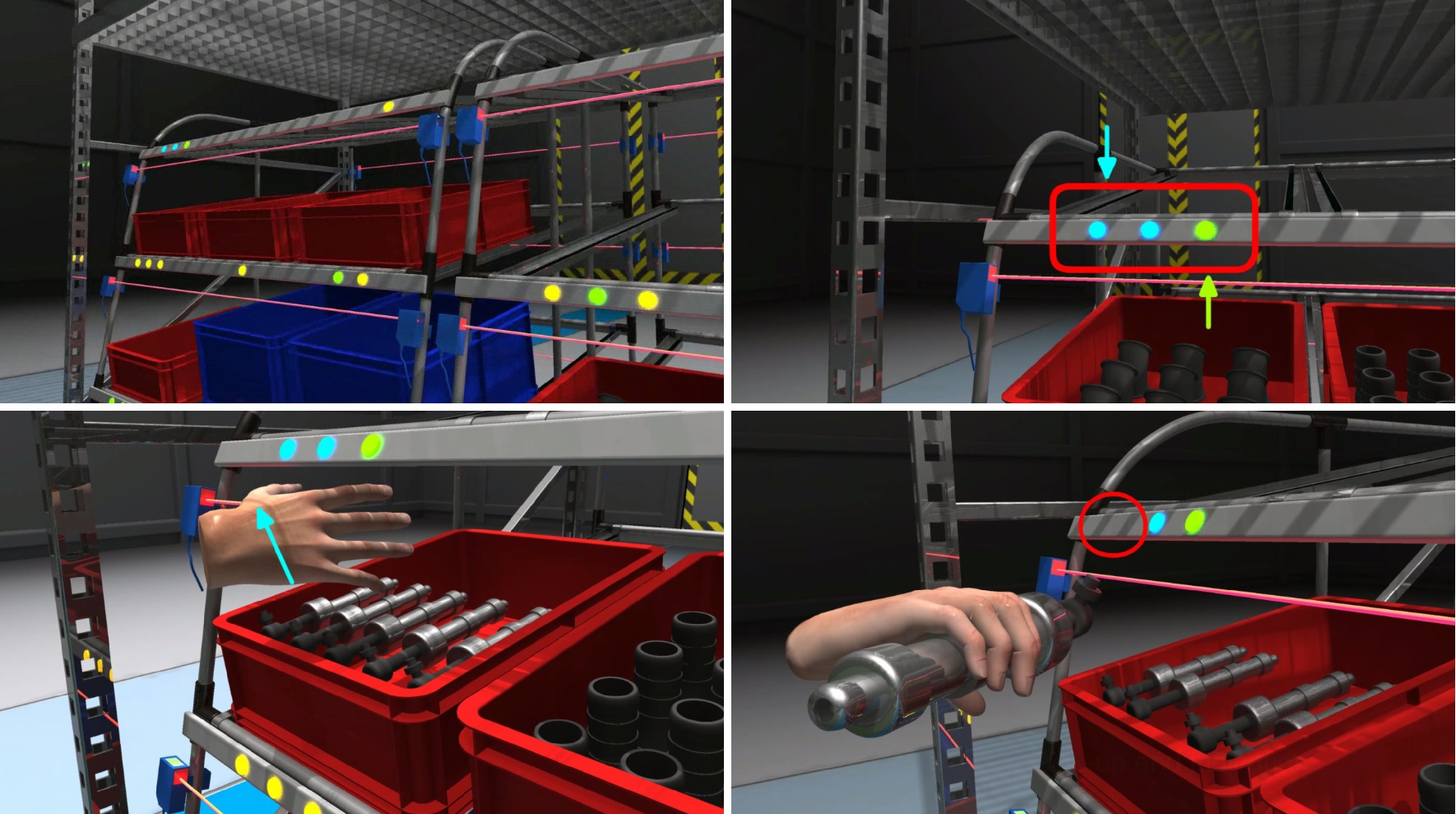

In order to make picking of parts for multiple vehicles possible, programmable RGB LED light strips have been used. Each protocol has its own color and the number of lit LEDs specifies how many parts are to be picked.

- The trolley is divided into 3 colors. Each contains parts for different vehicle.

- The operator is navigated to positions via programmable RGB LED strips.

- The paper regulations have been replaced digitally with the control of already loaded parts.

The combination of pick by light and push to light technologies lead to creation of a unique Manipulate 2 Light system, that is governed by an industrial design: PUV50145-2014. For the validation of picked components a laser sensor with a range of up to 10 m has been used.

- Number of lit LED lights equals the number of parts to be picked.

- Picking control using a laser sensor with a range of up to 10 m.

- Extinction after detection of picking.

The M2L system has been put into operation within 3 months.

The system is currently in use inside a warehouse with an area of 4000sqm and eight independent workstations.

The system is used to pick out of more than 2000 different parts for three different vehicle models of different makes.

Benefits:

- High modularity and flexibility

- Almost effortless installation

- Definition of size of a position achievable by a single hand gesture

- Colours differentiate between protocols

- Real-time stock overview

Results

- Average training time for a new operator has decreased by 85%

- The quality of order picking has increased and the number of errors has been minimized

- Multiple extension of workstation without supplementing the workforce

- Paperless workstation

- The workload has declined sharply and hence the demands for the quality of new operators

- DHL created a motivational video from the workstation with M2L to recruit new operators

The first phase has been successfully deployed in DHL and the solution has been in use since 2015. The next phase will be aimed at navigating the operator while loading the trolley for production line. In cooperation with University of Žilina we are working on image recognition that could serve as the last validation of the picked part. Using augmented reality we will record the image of a loaded trolley and archive it including a map of detected parts.

DHL is expanding our cooperation and incorporates other parts of our solutions like WMS, TLS and custom developed applications.

The president of the Automotive Industry Association Mr. Jaroslav Holeček has stated upon viewing our presentation of M2L as part of his visit at our premises in Žilina, that our solution are the right path towards Industry 4.0

Do not waste your resources, let us show you how to save.